Thermo-Brace® Structural Insulative Board (S.I.B) contains BASF Neopor® Graphite Polystyrene (GPS) rigid foam, which gives Barricade Thermo-Brace S.I.B. greater insulative value over competing sheathing materials like oriented strand board1 (OSB). Barricade Thermo-Brace S.I.B. is also non-toxic and has greater strength, superior moisture management, and saves time and money compared to OSB.

Thermo-Brace Structural Insulative Board

Barricade Thermo-Brace S.I.B. combines strength, two weather-resistant barriers (WRBs), and Neopor® Graphite Polystyrene (GPS) rigid insulation in one solution. Notably, Barricade Thermo-Brace S.I.B. has excellent long-term thermal resistance and is available in R-3 and R-5 thicknesses. It also complies with 2012, 2015, and 2018 International Energy Conservation Codes (IECC) for continuous insulative sheathing.

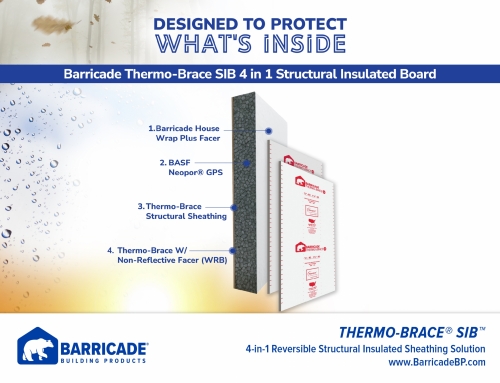

Barricade Thermo-Brace S.I.B. is composed of four layers:

- A safe-reflective facer WRB designed and guaranteed not to overheat the vinyl

- BASF Neopor® GPS rigid foam

- Barricade Thermo-Brace Structural Sheathing

- A second non-reflective facer WRB

Neopor® GPS Provides Insulative Quality to Barricade Thermo-Brace S.I.B.

What is Neopor Graphite Polystyrene?

Neopor® Graphite Polystyrene (GPS) is a highly efficient, rigid foam insulation (patented and manufactured by BASF) used in new construction and remodeling applications, like below grade, behind new siding, and below a slab. Neopor® GPS is energy efficient and has a permeability rating of 3.1. It is also GREENGUARD certified for Gold Indoor Air Quality.

How is Neopor® GPS Made?

Making Neopor® involves integrating high-purity graphite particles into polystyrene beads. Manufacturers, like BASF, convert the graphite polystyrene beads into rigid boards by placing them in a mold and hitting them with steam. The steam causes the beads to expand until they fill the mold.

Assembling Barricade Thermo-Brace S.I.B. involves sandwiching the GPS between Barricade Thermo-Brace Structural Sheathing and a WRB, which tremendously reduces thermal bridging.

What are the Advantages of GPS over Expanded Polystyrene Insulation?

Both GPS and expanded polystyrene (EPS) insulation slow the transfer of heat by trapping air (which is a poor conductor of heat) within their structures. The main difference between GPS and EPS insulation is GPS’s high-purity graphite particles. The graphite particles reflect heat hundreds of times as it moves through the insulation. The reflection significantly slows the transfer of heat, making Neopor® more energy efficient (R-value of 4.7) than traditional EPS insulation (R-value of 3.6).

Why Choose Thermo-Brace S.I.B Over OSB Sheathing?

Thermo-Brace S.I.B is non-toxic, provides greater strength, superior moisture management, and saves time and money compared to OSB.

The High Insulative Value of Barricade Thermo-Brace S.I.B. Over OSB

- The layer of Neopor® GPS in Thermo-Brace S.I.B give it greater insulative value (R-3 or 5) than competing sheathing materials like OSB (R-value of 0.5 – 0.62). Barricade Thermo-Brace S.I.B. R-value is nearly ten times the insulative value of OSB.

The Better Moisture Resistance of Barricade Thermo-Brace S.I.B. Over OSB

- Thermo-Brace S.I.B. has a WRB on both sides which provides excellent moisture management and mold resistance compared to OSB.

The Greater Strength of Barricade Thermo-Brace S.I.B. Over OSB

- Thermo-Brace S.I.B. is an alternative corner bracing technique with structural ratings better than OSB.

Other Advantages of Barricade Thermo-Brace S.I.B. Over OSB

- Unlike OSB, Thermo-Brace S.I.B. is formaldehyde-free.

- Thermo-Brace S.I.B. is less expensive than OSB.

- Thermo-Brace S.I.B. saves money over OSB because it is easy to install and lightweight, which saves time and labor.

- Barricade Thermo-Brace S.I.B. can help to offset the high and increasing costs of OSB

Contractors and architects who are looking for a structural sheathing product with high insulative value should consider Thermo-Brace S.I.B. Thermo-Brace S.I.B contains BASF Neopor® GPS rigid foam, which gives it greater insulative value over other sheathing materials like OSB. Other benefits of Thermo-Brace S.I.B. are it is non-toxic, has superior strength and moisture management, and saves time and money compared to OSB.

1Oriented strand board (OSB) is a panel sheathing made from hundreds of rectangular thin wood strands (1-inch by 4-inch flakes), arranged in cross-oriented layers. The cross-oriented layers create a durable panel that will not warp or bow. However, OSB is susceptible to dimensional instability and may expand and contract with changes in moisture. OSB also has a minimal thermal resistance (R-value of 0.5 – 0.62) and is susceptible to moisture intrusion, which can cause mold, decay, and swelling along the edges. In addition, OSB contains formaldehyde that can irritate the eyes and lungs.