Oriented strand board (OSB) prices are predicted to continue fluctuating, which makes projecting and maintaining budgets for future construction projects difficult. As a result, today’s contractors, architects, and building owners are wise to look for ways to offset high and volatile OSB prices. OSB is a conventional sheathing material used for subfloors, roof and wall sheathing. OSB is traditionally cheaper than plywood and other structural sheathings; however, a high demand over supply of OSB in recent years has caused OSB prices to escalate. Recently, OSB increased by 4.4 percent.

Since September and January 2016, OSB has increased 19 and 38 percent. According to Random Lengths, OSB composite price hit $494, the highest since March 2013 of $495. The low inventory of OSB may be because distributors want to minimize a potential oversupply of OSB. Also, natural disasters, like hurricanes and fires, have increased the demand for OSB. Finally, the current administration’s duty rates on Canadian lumber is impacting OSB and lumber costs. As OSB prices continue to rise because of reduced production and increased demand, contractors and building owners look for ways to offset the high OSB prices.

The manufacturing of OSB involves pressing wood bits together and bonding with adhesive resin and glue. OSB’s popularity as a sheathing product took off in the 1970’s due to a decline in the availability of timber suitable for plywood production. Sheathing holds the studs together that give the building structural integrity (wall bracing), provides a surface for fastening siding materials, and can also provide thermal properties critical to HVAC air retention. By the 1980s, OSB was a leading commercial structural sheathing material, mainly due to its lower price over other sheathing materials. Another advantage of OSB is its size. Oriented strand boards are large, tall panels, which makes for fewer horizontal seams than plywood panels.

A significant problem with OSB is every cut in OSB is susceptible to moisture, and it swells when wet. A buildup of moisture within a building’s wall cavities is problematic because moisture can lead to fungi and wood rot. High moisture can also cause mold, which is unhealthy for the occupants of the building. Another health concern with OSB is it contains PF resins, which emits low levels of formaldehyde. Formaldehyde can cause breathing problems, irritation of the eyes, nose, throat, or skin and even cancer. OSB is also heavier and not as stiff as plywood and can produce squeaky floors. Finally, OSB is challenging to paint. Contractors and building owners consider alternatives to OSB as they struggle with high OSB prices, along with OSB problems with moisture, flexibility, and formaldehyde emissions.

OFFSET HIGH OSB PRICES WITH COST-EFFECTIVE ALTERNATIVES LIKE FIBERBOARD SHEATHING

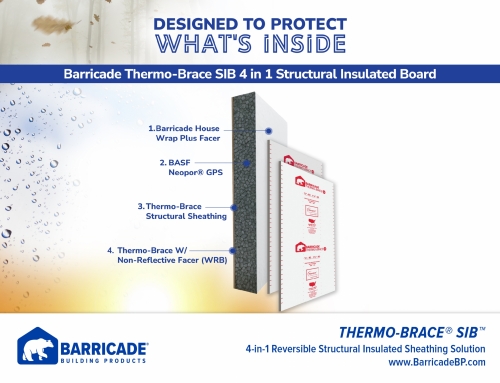

Barricade Thermo-Brace® is an exterior wall sheathing that solves many of the problems of OSB: high and volatile prices, moisture issues, and toxic emissions. Thermo-Brace is also strong and can protect a building against increasingly dangerous weather events caused by global warming.

- The strength of Thermo-Brace saves money over OSB because there is less worksite damage, which reduces replacement costs. Thermo-Brace also saves money because it is easy to install and lightweight which saves labor and time. Additionally, Thermo-Brace is available in custom dimensions which means less waste and site clean up.

- Thermo-Brace provides excellent moisture management because its ⅛ inch thickness forms a tight seal to the framing members which gives excellent protection against water and air infiltration. Also, the long fibers of the Thermo-Brace’s core are specially-treated with water and weather-resistant plies. These plies are pressure laminated with a water-resistant adhesive. All grades of Thermo-Brace are permitted as water-resistive barriers as noted in IRC section R703.2 and IBC Section 1404.2.

- Thermo-Brace is formaldehyde free.

- Thermo-Brace comes in three grades; each made of high-quality, long fibers that add dimensional stability and strength. All grades of Thermo-Brace resist lateral forces of wind, storms, and earthquakes and Thermo-Brace is an alternative corner bracing method with structural ratings equivalent or better than OSB.

Oriented strand board (OSB) prices are up almost 20 percent since September 2016. In contrast, other building products have increased to a lesser amount: ready-mix concrete (up 0.2 percent) and gypsum products (up 0.3 percent). Increasing OSB prices are due to demand over supply, increasing construction starts, and several natural disasters. As contractors, architects, and building owners struggle to offset the high OSB prices, an excellent alternative sheathing product to consider is Barricade Thermo-Brace. Thermo-Brace construction and simple installation save time and money. Thermo-Brace is also durable, moisture and air resistant, and formaldehyde free. Visit Barricade Thermo-Brace® for more information on how to offset the high rise of OSB prices.