Barricade Thermo-Brace® provides greater strength, superior moisture management, is non-toxic, and saves time and money compared to oriented strand board (OSB) and fiberboard structural sheathings.

Structural exterior wall sheathing works with the building envelope to prevent wind and water from entering. Structural wall sheathing also ties framing studs together, makes the walls resistant to twisting and bending, and provides a surface for application of materials, like siding. However, many structural exterior wall sheathings, like OSB and fiberboard, lack sufficient strength, effective moisture management, may contain toxins, are difficult to handle, and have escalating and volatile pricing.

OSB vs. Fiberboard Structural Sheathing

Two common types of structural wall sheathing are oriented strand board (OSB) and fiberboard sheathing. They attach to the exterior wall framing and brace the walls against positive and negative forces. Both are wood products, which makes them earth friendly. However, there are several differences between OSB and fiberboard structural sheathing.

- OSB is stronger than fiberboard sheathing

- Fiberboard sheathing does not hold screws as well as OSB

- Fiberboard has slighter greater insulation value than OSB

- Both are susceptible to mold, wood rot, and swelling due to moisture intrusion; however, fiberboard is more permeable than OSB.

- Fiberboard is not, while OSB is susceptible to dimensional instability and may expand and contract with changes in temperature.

- Fiberboard is less expensive than OSB.

Oriented Strand Board Structural Sheathing

Oriented strand board (OSB) is a panel sheathing made from hundreds of rectangular thin wood strands (1-inch by 4-inch flakes), arranged in cross-oriented layers. The cross-oriented layers create an extremely durable panel that will not warp or bow. The strands are hot pressed onto sheets with a resin and wax adhesives. OSB come in sizes up to 8 feet wide and 16 foot long and is used in commercial and residential construction

Structural Sheathing OSB Pros:

- OSBs are durable panels that are solid and dense throughout the product, with no soft spots.

- OSB is stronger than fiberboard sheathing.

- OSB holds fasteners well and creates a strong bond between studs.

- OSB is manufactured in large, tall panels, and can reach from floor to ceiling with one sheet.

Structural Sheathing OSB Cons:

- OSB is susceptible to dimensional instability and may expand and contract with changes in temperature.

- OSB requires significantly more processing and energy to manufacture than fiberboard, so it has a bigger environmental impact and contributor to global warming than fiberboard.

- OSB contains formaldehyde that can irritate the lungs and eyes.

- OSB is vulnerable to swelling at the edges due to moisture intrusion.

- OSB is susceptible to mold due to moisture intrusion.

- OSB is vulnerable to decay if the moisture content is near 30 percent.

- Oriented strand board (OSB) prices increased by 3 percent between February and April 2018. Other building products have increased to a lesser amount: ready-mix concrete (up 3.3 percent), soft lumber (2.2 percent) and gypsum products (up 0.3 percent). Increasing OSB prices are due to demand over supply, increasing construction starts, and several natural disasters.

Fiberboard Structural Sheathing

Fiberboard structural sheathing is an engineered product made with ground up wood chips and lumber waste glued together with an asphalt binder or resin. The finish of fiberboard is uniform, with no knots or grains like those found in real wood. Structural sheathing is available in nominal ½-inch and 25/320-inch thickness and 4-foot x 8-foot and 4-foot x 9-foot square edge.

Fiberboard Structural Sheathing Pros:

- Fiberboard has more thermal resistance than OSB. Fiberboard (½-inch) has an R-value of 1.3. OSB (½-inch) has an R-value of 0.5 – 0.62.

- Fiberboard is less expensive than OSB.

- Fiberboard is dimensionally stable, so resistant to expansion and contraction.

- Fiberboard sheathing permits water vapor generated inside the structure to pass through the wall cavity, thus reducing the potential of trapped water within the wall.

- Fiberboard sheathing is consistent throughout, so cut edges are smooth, without voids or splinters, and can create decorative edges.

- Fiberboard sheathing is an earth-friendly material.

Fiberboard Structural Sheathing Cons:

- Fiberboard sheathing has less strength than OSB. Fiberboard requires products or techniques to provide wind bracing and rigidity to the structure.

- Fiberboard sheathing does not hold screws well; it is also easy to strip the screw holes.

- Fiberboard sheathing is heavy because it is so dense, which can make it difficult to handle.

- Fiberboard sheathing releases small amounts of asphalt odor, especially when heated by the sun.

- Fiberboard sheathing emits low levels of formaldehyde.

- Fiberboard sheathing is often heavily treated with flame retardants and impregnated with asphalt, which eliminates the potential for composting and limits recycling options.

- Fiberboard sheathing is susceptible to swelling at the edges due to moisture intrusion unless it’s sealed on all edges and sides with primer, paint, or another sealing product.

- Fiberboard sheathing is susceptible to mold due to moisture intrusion.

- Fiberboard sheathing is vulnerable to decay or wood rot if the moisture content is near 30 percent.

Avoid the Cons of OSB and Fiberboard with Barricade Thermo-Brace®

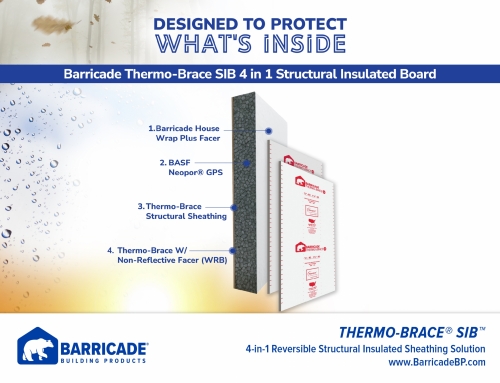

Barricade Thermo-Brace® is a far superior structural sheathing over OSB and fiberboard structural sheathing: greater strength, superior moisture management, non-toxic, saves time and money and can offset the increasing costs of OSB.

- Thermo-Brace is an alternative corner bracing technique with structural ratings better than OSB and fiberboard.

- Thermo-Brace strength provides more protection against dangerous weather events than OSB and fiberboard.

- Thermo-Brace provides excellent moisture management, compared to OSB and fiberboard, because Thermo-Brace ⅛-inch thickness forms a tight seal to the framing parts which gives superb protection against water and air infiltration. In addition, the long fibers of the Thermo-Brace’s core are specially-treated with weather- and water-resistant plies. The plies are pressure laminated with a water-resistant adhesive. All grades of Thermo-Brace are permitted as water-resistive barriers as noted in IBC Section 1404.2 and IRC section R703.2.

- Unlike OSB and fiberboard, Thermo-Brace is formaldehyde free.

- Thermo-Brace is less expensive than OSB.

- Thermo-Brace saves money over OSB and fiberboard because it is easy to install and lightweight which saves labor and time.

- All grades of Thermo-Brace are made of high-quality, long fibers that add dimensional stability and strength that saves money over OSB and fiberboard because there is less worksite damage, which lessens replacement costs.

- Additionally, Thermo-Brace comes in custom dimensions which means less site clean up and waste.

- Barricade Thermo-Brace can help to offset the high and increasing OSB prices.

Structural exterior wall sheathings, like Barricade Thermo-Brace®, OSB, and fiberboard all work with the building envelope to prevent wind and water from entering tie framing studs together and makes the walls resistant to twisting and bending. They also provide a surface for application of materials, like siding.

Barricade Thermo-Brace®, however, provides more strength, better moisture management, is non-toxic and saves time and money compared to OSB and fiberboard structural sheathings.