Oriented strand board (OSB), with a thin layer of low emitting aluminum foil attached to one side, is a common type of thermal-radiant-barrier sheathing. Foil-backed OSB is applied mostly in attics; however, it is also used in wall systems. The goal of a foil-backed OSB is to cool the air within the top layer of insulation in the attic or wall by emitting the radiant heat absorbed through the roof or exterior walls, which reduces the Delta-T and lessens the overall energy use in a building.

What is Delta-T?

Delta-T is the difference between the temperature of the top layer of insulation in the attic or wall system and the living spaces. For example:

During the hot summer, the heat of the sun can raise the temperature of the top shingles of the roof to nearly 180 degrees. The bottom of the roof deck will be 20 or 30 degrees lower.

Through the process of infrared radiation, the heat from the roof is emitted (or radiated) into the attic where the insulation absorbs it. When this occurs, the top surface of the insulation can reach a temperature of 130 degrees and more, which is much higher than the temperature in the living spaces (68-70 degrees). The Delta-T is the difference in temperature between the top layer of the insulation and the living spaces.

The foil layer of the OSB lowers the Delta-T because the foil is low emitting and does not emit or absorb heat. So, when the sun hits the roof and radiates into the attic or wall, the foil layer of the OSB sheathing reflects the heat to the roof or exterior wall, which keeps the top layer of the insulation just a few degrees warmer than the outside air temperature. Similarly, when heat rises into an attic during cooler months, the foil layer reflects it into the living spaces of a building. Without the foil layer, the OSB sheathing will absorb heat and radiate it into the attic space in the summer, or outside during the winter.

Adding more attic ventilation will help, but not much. Even with excellent airflow in an attic, the temperature of the top surface layer of the insulation will only drop a few degrees.

Five Problems with Foil-Backed OSB Radiant Barriers

- The foil layer of the OSB lowers the Delta-T by reflecting the thermal energy due to radiation (sun’s heat) away from the insulation layer, which keeps the top layer of the insulation just several degrees warmer than the outside air temperature. However, foil-backed OSB often requires additional thermal insulation to prevent the transfer of thermal energy by conduction and convection.

- Only clean and shiny foil will emit heat. Dust and dirt make the foil less reflective. Dirt and dust are particularly problematic in attics where the foil-backed OSB is applied horizontally, which makes it prone to dust and dirt. It is crucial to keep the workspace clean when installing foil-backed OSB.

- Foil-backed OSB acts as a vapor barrier, particularly when it is cold outside. If water vapor from the interior of the building moves into the attic, and the foil-backed OSB is cooler than the dew point, the moisture may condense on the underside of the barrier. When installing foil-backed OSB, builders must pick a location where the barrier is unlikely to reach the dew point temperature.

Condensation on the underside of foil-backed OSB can cause several problems:- If the insulation becomes damp, it will lose some of its insulating values

- Water spots may appear on the ceilings of the living spaces

- Moisture can lead to mold which is both unhealthy to the occupants of the building and can rot the ceiling framing or wall assembly

- For foil-backed OSB to perform correctly, builders must make sure there is an open air space adjacent to the foil layer not less than ¾ -inch. If the foil-backed OSB comes in direct contact with other materials, like rafters and wall framing, heat will transfer through conduction from the foil-backed OSB to the adjacent materials. One reason contractors avoid using foil-backed OSB in wall systems is because it is hard to create the air gap needed for foil-backed OSB to work properly.

- The Oak Ridge National Laboratory found that roof mounted foil-backed OSBs may increase roof shingle temperatures by 2 to 10 °F. Similarly, foil-backed OSBs installed on the attic floor may increase roof shingle temperatures by 2°F or less. Unfortunately, higher roof temperatures may reduce the roof’s service life.

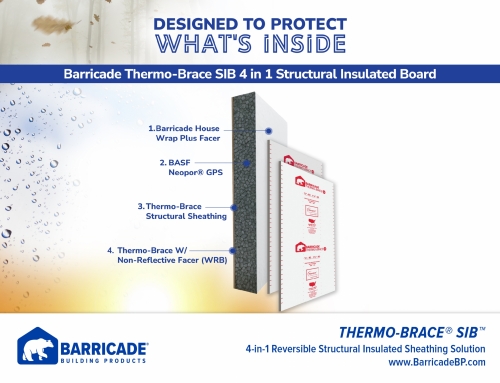

Why Barricade® Thermo-Brace® S.I.B. is a Better Thermal Barrier Than Foil-Backed OSB

A better thermal barrier to foil-backed OSB is Barricade Thermo-Brace® S.I.B. Specifically, Thermo-Brace® S.I.B, with weather resistant barriers on both sides, is more moisture resistant and limits thermal conduction and convection more effectively than foil-backed OSB. Importantly, the installation of Thermo-Brace® S.I.B saves builders time and labor over foil-backed OSB.

- Thermo-Brace® S.I.B has high thermal resistance and low thermal conductivity, which makes it a good insulator because to inhibits thermal conduction.

- A high-performing thermal barrier, like Thermo-Brace® S.I.B, is air-resistant and limits thermal convection.

- Thermo-Brace® S.I.B saves money over foil-backed OSB because Thermo-Brace® S.I.B is lightweight and easier to install than wall application of foil-backed OSB, which saves builders labor and time.

Thermo-Brace® S.I.B. creates a superior thermal barrier compared to foil-backed OSB barriers. Barricade Thermo-Brace® S.I.B. has high thermal resistance and low thermal conductivity; both features essential to controlling air and moisture infiltration into a wall system.