Substantially more stable pricing than other sheathings and the ability to be installed with the structural board facing out, for more “field durability,” or foam side facing out (both sides are conveniently printed, it’s your choice) has Thermo-Brace SIB flying out of the lumber yard.

Exterior sheathing that’s lighter and less expensive than the competition with an R3 or R5 insulated value is an easy sale in most places in the country, but wait, there’s more. Imagine an innovative building science product that has a weather-resistive barrier (WRB) on both sides and you’re getting a taste of Barricade’s Thermo-Brace SIB. Structural Insulated Boards (SIB) changed how things are done on the job site and it’s time to move to the next level.

Nailed It

Most structural insulated boarding is designed to be stapled in place with the foam-side facing out and that’s where the Thermo-Brace SIB difference continues. “Our product is designed to use the structural panel on the outside so you can nail it with a one and a quarter inch nail,” says Mid-Atlantic Barricade Sales Rep., Michael Rehman, who is based in Harrisburg, Pennsylvania.

Trading out the practice of nailing into board instead of stapling into foam is a no-brainer for builders, but it gets better. “Our boards are all labeled,” says Rehman. “If you’re building sixteen inches on center, there’s a dot or a line every three inches to show you where you hit it with a nail. As long as you follow the installation patterns, it’s very simple. Our competitors don’t do that.”

Four Layers of Goodness

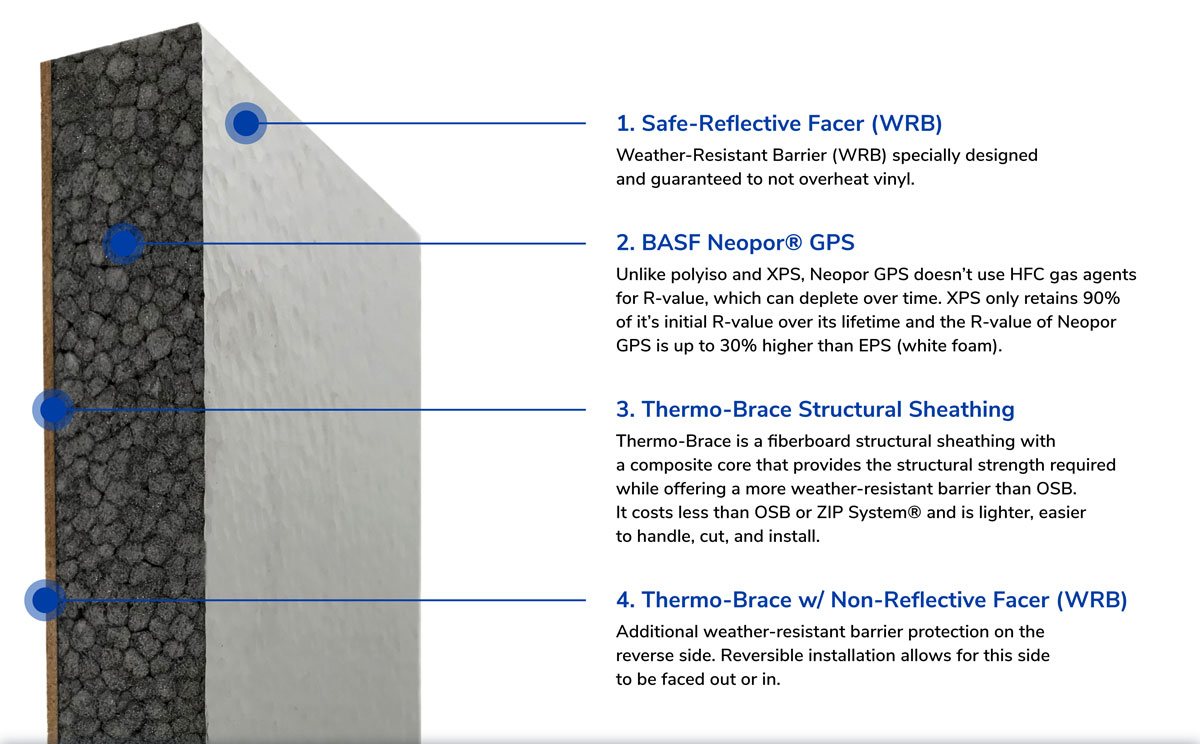

Thermo-Brace SIB brings four desirable ingredients to every picnic. “First of all, it’s structural, and we’re using the best lightweight panel backer on the market,” says National Sales Manager Darcy Overby, who is based in Dallas. “The panel itself is our Thermo-Brace Red which uses virgin kraft board as opposed to a recycled product, which is what our competitors use.”

The board has a WRB coating which creates a weather-resistant barrier and an air barrier. Say goodbye to the time and expense of house wrap. Eliminating OSB from the equation also reduces the risk of water damage. “Resistance to mold is a value-add,” says Rehman. “Everybody knows that if something goes wrong and water hits OSB it’s going to rot and create mold.” The foam in the center of the sandwich also contains some secret sauce.

The Neopor® Edge

Neopor is an insulation product developed in Germany by BASF, which is the largest chemical company in the world. Neopor was designed to compete with the big boys and has been used in the bitter cold and temperate climates of Europe for years. It’s especially competitive with Polyisocyanurate (Polyiso), which actually performs worse the colder it gets.

The performance decline starts when temps drop below 60 degrees and things get worse the colder it goes. Polyiso is also susceptible to moisture damage and it has issues with loss of R-Value over time.

Neopor is a completely different material that reflects radiant heat energy, increasing the material’s resistance to the flow of heat, or R-value. “It holds in the R-value much better than other types of foam,” says Overby. “It provides thermal brakes from the exterior wall to the studs to the interior walls. With OSB you need to add foam and a house wrap to get the same combination.”

Doing the Math

The added emphasis on indoor air quality and tightening building codes is accelerating the adoption of Barricade’s Thermo-Brace SIB. The product is already popular in cooler climates because it helps builders hit the required R-value without overstuffing insulation into walls.

“Sometimes it’s hard to fit R-16 insulation inside a two-by-four wall,” says Rehman. “With OSB, once you add an inch of foam and 7/16 plywood on it, you’re pretty close to two inches. With the Thermo-Brace SIB, we’re sitting on R-5 and we’re only one and 1/16 inches thick.” Going too thick can create foundation overhangs. In the south and southeast, Overby is seeing new interest in the product due to building codes becoming stricter.

Bottom Line

When crunching the numbers to reach the required R-value at the right price, all the pieces of a wall system have to be added in including the cost of the insulation, weather barrier, air barrier and house wrap. The market price for OSB fluctuates with rises and falls in the commodity markets due to the high concentration of lumber used in its construction. Barricade’s Thermo-Brace line acts as a protective hedge against whatever is happening on Wall Street.

“Even if OSB drops in price, you still have a four-in-one panel saving time, money, and labor,” says Overby. “With Barricade’s Thermo-Brace SIB, you can get rid of the house wrap.” With tighter building envelopes, HVAC systems can be sized smaller and utility bills shrink.

Closing Arguments

Barricade’s Thermo-Brace SIB offers performance and pricing that large production builders in the U.S. and in Europe already know about. It’s half the weight of OSB which makes it easier to move, place, and fasten. It complies with the International Energy Codes established in 2012, 2015, and 2018 for continuous insulative sheathing.

It uses non-toxic materials and according to UL, it’s a certified Greenguard product which means it is “scientifically proven to meet some of the world’s most rigorous third-party chemical emissions standards, helping to reduce indoor air pollution and the risk of chemical exposure.”

The boards reduce thermal bridging, the process of heat moving through walls that accounts for a major source of energy loss in homes. Thermo-Brace SIB is an energy-efficient and cost-effective insulated solution for architects, contractors, and builders. Cost savings are estimated to be 30% when compared to OSB, insulation, and house wrap. Thermo-Brace SIB is proudly made in Doswell, Virginia, and did we mention that it can be fastened with nails, not staples?

To get a quote on how much you can save by using Thermo-Brace SIB or to explore stocking options, learn more.